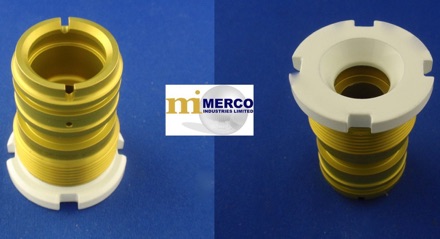

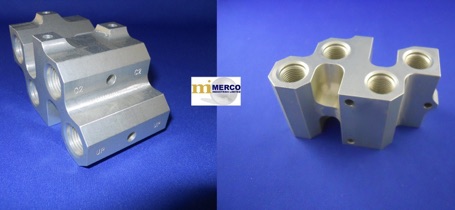

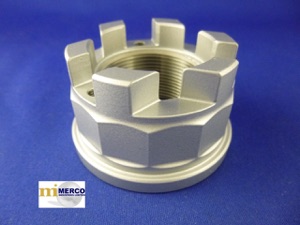

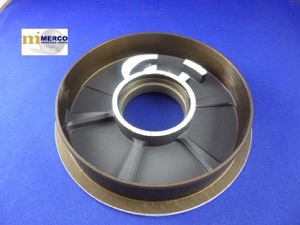

PRECISION MACHINED COMPONENTS AND ASSEMBLIES

QUALITY

CONTROL

ON TIME DELIVERY

CUSTOMER SATISFACTION

100%

Our extensive, leading-edge computer-aided manufacturing software and equipment allows us to produce precision parts and assemblies in virtually all metals, plastics and composites including:

solid stock, castings or forgings, aluminum, steel, stainless steel, aluminum bronze, copper, super alloys, nylon, teflon, delrin and various plastics.

We are capable of milling parts up to 38” X 20” X 20” and turning parts up to 13” in diameter X 18” long. Currently employing 35 highly skilled personnel, having at our disposal some of the most advanced state of the art technology and equipment which allows us to maintain our continued goal of achieving the highest quality standards in the industry.

People are an important part of any business, but especially in the highly precise nature of manufacturing aerospace components. It is for this reason that we feel strongly that those persons employed at Merco Industries maintain the same commitment to quality which was established when this company was created. Our core labour force has been with the Merco family for an average of 20 years.

Presently we are working at 60 to 70 % of our normal capacity, hence we are able to accommodate a large influx of new work into our workplace and still maintain our excellent level of quality and on time service.

© COPYRIGHT MERCO INDUSTRIES LIMITED 2025. ALL RIGHTS RESERVED.